AC High-voltage Ionizing Air Gun Spray Gun For Film , Injection Molding Industry

![]()

Product description

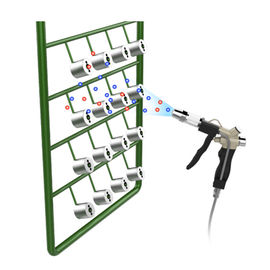

AP-AC2456 ionizing air gun is produced by Anping Company (AP&T) to eliminate static electricity on the surface of objects. It is a fast and efficient dust removal device designed to provide electrostatic protection for the surface of the target object.

AP-AC2456 ionizing air gun uses AC high-voltage electricity and is connected to a dedicated emitter electrode to ionize the air to generate positive and negative ions. The compressed air is transported to the surface of the static-eliminated object to neutralize the positive and negative electrostatic charges to discharge efficiently.

![]()

![]()

Industry application:

Can be widely used in electronics, injection molding, printing, film industry and other industries.

Features:

1) Small size and portable to operate.

2) Excellent electrical performance index and good performance.

3) Fast static & dust removal.

4)Safe and reliable to work under the condition of high voltage and micro current.

5) Configure AP-AC2455-28 special high-voltage power supply.

![]()

![]()

![]()

3. Technical tips

① Ionizing air gun should be placed in the work area where static electricity is eliminated.

(It is better to be about 150-300 mm from the surface of the static electricity object.)

The discharge angle should be perpendicular to the surface of the charged body.

② The entire device must be reliably connected to the ground wire and the ground resistance is less than 4 ohm.

③ The surface of the ionizing air gun shall not be covered with anything else.

Fault solution:

| No. | Problems | Possible reason | Solution |

| 1 | Discharge performance is significantly reduced | Discharge needle pollution and damage | Clean or replace the electrode needle |

| 2 | Reduced discharge performance | There are conductors or other consumers around the ion air gun | Remove (moving) conductor or other consumer |

| 3 | Can't discharge | Damaged high-voltage cable | Return to factory for repair |

| Ion air gun insulation damage | Return to factory for repair | ||

| Poor grounding/no grounding | Check the electrical grounding of ion air gun, high voltage power supply and plant equipment | ||

| 4 | Product burn | Ion air gun insulation damage | Return to factory for repair |

Maintenance

1. In order to ensure the good performance of the product, it should be cleaned and maintained in time according to the use environment and the required electrostatic protection requirements, that is: use an electrostatic brush, a dust-free cotton swab, a dust-free cloth dipped in anhydrous alcohol, and gently remove it. The performance of carbon deposits or white products on the electrode will be significantly improved. note:

A. It must be operated 10 minutes after the power is turned off.

B. During the use of the ion air gun, when a white product appears on the needle tip, it must be cleaned. When the brush can not meet the cleaning requirements, you can use a clean cotton swab dipped in absolute alcohol for cleaning.

C. After cleaning, you must wait for the alcohol to completely volatilize before working with electricity. You cannot use any other organic solvents to clean the air gun.

2. It is found that the ion air gun burns, and it should be stopped and checked and repaired by professional maintenance personnel. It can be used only after the electrical performance index is normal.

After-sales service

1. The AP-AC2456 ion air gun has undergone rigorous testing, inspection and aging treatment before leaving the factory, and its performance has fully reached the relevant indicators marked in the instruction manual.

2. AP&T makes the following commitment to users: within one year from the date of purchase, our company will repair or replace any parts that have been defective after inspection by our company free of charge. However, this commitment does not apply to the following situations:

1) The equipment is misused and installed;

2) Damage caused by negligence or accident during use;

3) Modified, disassembled or repaired by other non-Anping authorized service department.

3. The alloy electrode is a consumable item, which is not covered by the warranty. The company must charge for replacement when repairing it for customers.

4. Except for the repair or replacement of parts in this regulation, AP&T shall not bear any obligations and related responsibilities of product users.

Packaging accessories

1. Warranty card 2. Manual 3. Qualification certificate

About Anping:

Shanghai Anping Static Technology Co.,Ltd was established in 1999 which is the first Hi-Tech enterprise researching and manufacturing DC ionizer in China.

Our AP&T brand series products include ionizing air blower, ionizing air gun, ion bar, ion nozzle with various specifications are wildly used in semi conduct, encapsulation, opto-electrical, electronics, communication, spray finishing, printing, textile, pharmaceutical equipments, construction material, injection molding industries. Our products have won good reputation of our users and have been exported to Japan, Korean, South East Asia, Europe , North and South America.

As councilman of China Electronics lndustry Association Anti-static Equipment Branch, we devote our efforts in providing comprehensive perfect solution of static control and eliminating and serve our customers with our strong technical strength and rich industry experience. We are ready to supply you over valued products and technology. We’ll be your reliable partner in ESD field.